|

|

|

|

|

|

| |

|

|

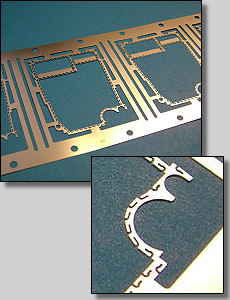

Chemical etching is a low-cost alternative to stamping tools utilized for prototyping and low-volume production.

| Composidie Inc. can support your production requirements with our Leading Technologies, Inc.

etching facility. |

| ▪ High Speed, Continuous Process |

| ▪ Non-Contact Glass Mask |

| ▪ 0.002" to 0.025" Thick Materials |

| ▪ Dry Film Type Photoresist |

▪ Automated vision alignment system

for

exposure assures

+/- 0.0005"

(0.0127mm) offset mismatch |

▪ Accurate unit-to-unit progression

tolerance of +/- 0.001" (0.025mm) |

| ▪ Leadframe, Connector, RF/EMI Products |

▪ Major benefit in prototyping designs

due to inexpensive tooling costs and

shorter lead times. |

Etch Design Guidelines

Material

Thickness |

Typical |

Advanced |

Minimum

Channel Size |

Minimum

Hole Size |

Minimum

Radius |

Minimum

Channel Size |

Minimum

Hole Size |

Minimum

Radius |

.003'' |

.0029'' |

.0059'' |

|

.0026'' |

.0053'' |

|

.004'' |

.0034'' |

.0064'' |

|

.0031'' |

.0058'' |

|

.005'' |

.0039'' |

.0068'' |

.0046'' |

.0035'' |

.0062'' |

.0040'' |

.006'' |

.0046'' |

.0074'' |

.0057'' |

.0039'' |

.0067'' |

.0050'' |

.007'' |

.0049'' |

.0079'' |

|

.0044'' |

.0072'' |

|

.008'' |

.0052'' |

.0084'' |

.0068'' |

.0047'' |

.0076'' |

.0060'' |

.010'' |

.0062'' |

.0095'' |

.0069'' |

.0056'' |

.0086'' |

.0065'' |

Note: Each product's features must be evaluated individually. This chart is only

intended to provide capability guidelines. |

Typical Material Thickness:

.005'' to .010" |

Advanced Material Thickness: .002'' to .004''

& .011'' to .023'' |

Top-to-Bottom

Mask Registration:

.0005'' Maximum |

Unit-to-Unit Progression Tolerance:

+/- .001'' |

Strip Pitch

Tolerance:

+/- .002'' |

Maximum Stair Step Tolerance:

.0015'' |

1/2 Etch Depth Tolerance:

30% to 60% of Material Thickness |

Min. Part

(Strand) Width:

.

500'' +/- .002'' |

Max. Part

(Strand) Width:

5.000 +/- .002'' |

Etch Tooling Guidelines

Mylar Tool

|

vs. |

Chrome/Glass Tool |

| Low Cost

-----

Best for Low-Volume

Production

-----

Fast Delivery

(2-3 Days)

-----

Geometry Confirmation

Prior to Chrome Tool |

Pros |

Permanent

-----

Best for

High-Volume

Production

-----

Highest Precision

& Accuracy

-----

Greatest

Clarity/Flatness |

| Scratches Easily

-----

Not Capable of Highest Resolution (Accuracy)

-----

Less Stable

(Guaranteed for 1500') |

Cons |

Higher

Cost

-----

1-Week

Leadtime |

We can provide the right tool for every job! |

|

|

|

|

©

Copyright Composidie Inc. 2007

|

|

| |

HOME | SITEMAP | DOWNLOADS

|

COMPOSIDIE INC.

1295 Route 380, Apollo, PA 15613-9658

Phone: (724) 727-3466

Fax: (724) 727-3788

|

PRIVACY | CONTACT | CAREERS

|

|